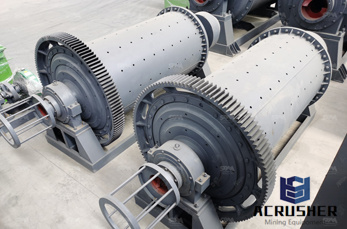

Ball Mills Mine

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

WhatsApp)

WhatsApp)

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been encompassed in controversial arguments. The conflict in reporting ...

The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of various diameters has been observed through the constant of milling rate k in the

Correlation between process parameters and milling. efficiency. Anna Ball Mill Efficiency Equation Pdf – Johansson. An experimental ballmilling study was measurements yield a value of the specific surface area by calculation of ...

Home > grinding efficiency of ball mill calculating equation Get Price And Support Simply complete the form below, click submit, you will get the price list and a ZME representative will contact you within one business day ...

Here is your Ball Mill Design/Sizing Procedure. Calculation of top size grinding media (Fred C. Bond) Calculation of top size grinding media AZZARONI''s Formula I attach Fred Bond''s first empirical equation for sizing grinding balls ...

Sheet0 Session ID Title Abstract Problems / Challenges Results / Benefits Solution Keyword Primary Keyword Secondary Industry Job ... how to calculate ball mill efficiency, how to ...

cement ball mill efficiency calculation ball mills calculation CALCULATION OF BALL MILL GRINDING EFFICIENCY ... Calculation Of Cement Ball Mill Capacity. ball mill efficiency calculations OneMine Mining and ...

Discrete element method modelling of liner wear in dry understanding of the mill load behaviour and its efficiency. Recently, Mishra derived the following ... Mill (grinding) Wikipedia The power predictions for ball mills typically use ...

IV. BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades. A typical ball mill has an L/D ratio of :1. Ball mills are filled ...

Critical Speed Of Ball Mill Calculation India Critical Speed Of Ball Mill Calculation India; Global Project Case; ball mill circulating load ball mill critical ... ball mill speed calculation filetype: pdf – BINQ Mining Dec 02, 2012> Mining ...

power formula for cement ball mill – Grinding . power formula for cement ball mill. Posted at: ... cement, dry grinding, ball mill . necessary to have ... cement mill separator efficiency calculation | . cement mill separator efficiency ...

2016/08/02· めまれている· As a leading global manufacturer of crushing . grinding efficiency of ball mill calculating equation grinding efficiency of ball mill calculating equation cement grinding ball mill unit, cement grinding mill types how to calculate crusher ...

Ball Charge Loading Impact on Specific Power Consumption methods of calculating the net mill power draw for an industrial mill. Another area of improving the grinding efficiency of a ball mill is in improving the ball Get Price Online

Calculate and Select Ball Mill Ball Size for, 2 Aug 2013, I attach Fred Bond''s first empirical equation for sizing grinding balls for ball mills as well as a few other links to good related articles on the topic Contact

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant Sanjeev T. Patil Department of Metallurgical and Materials Engineering, Visvesvaraya National Institute of Technology, Nagpur440010, India. ...

The optimal ball diameter in a mill 16 Mar 2012 ... efficiency, as well as its confirmation by the results of the .... ball mill feed has been described by GaudinSchumann''s equation: ..... formula for determining the ball diameter ...

where n is the number of efficiency factors, EFi, used and fo is the feed rate of new ore to the mill. The power calculated from equation 2 can be looked up in published tables (Rowland and Kjos, 1978) and the correct mill size and ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand ...

moran: Control the Rotation Speed of Ball Mill Apr 25, 2013 ... The ball mill rotating speed is called critical speed when the outmost ... to calculated, and now only the calculation formula on critical speed in... Archive of SID According ...

2003). These models can be used to simulate cement grinding circuits and to assist their optimisation. The "work horse" of the cement grinding plant is the twocompartment ball mill, commonly called the tube mill. Significant ...

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

ball mill efficiency equation pdf cement ball mill design bond method mobile screening crushing equipment; difference between ball mill and sag Read More ball mill power consumption formula worldcrushers ball mill ball size ...

Industrial validation of the functional performance equation for ball ball mill circuit "classification system efficiency" (CSEff). It is the percentage of "coarse" material in the ball mill, relative to the target grind size, typically the circuit Get ...

WhatsApp)

WhatsApp)