Make a Ball Mill in 5 Minutes: 4 Steps

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

WhatsApp)

WhatsApp)

Intro: Make a Ball Mill in 5 Minutes. This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or ...

The design velocity is significant with reference to the critical velocity .Critical velocity is an important parameter for a Slurry. When Slurry flows at velocity ...

coal hammer mill design[crusher and mill] Hammer Mill Design Mini Project – Free download as PDF File (.pdf), text . The basic design of the industrial hammer ...

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

Yet Another Ball Turner for the Lathe. There are lots of designs for ball turning attachments out there so it''s hard to believe that another one is needed.

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Angular contact thrust ball bearings, double direction, superprecision; Angular contact thrust ball bearings for screw drives, single direction, superprecision

How Does a Hammer Mill Work? [Slideshare] Posted October 1, 2014 by Schutte Buffalo

This just gave you some idea on how to start your design. It''s up to you how you want to continue that.

Manufacturing and exporting deep groove and angular contact ball bearings, pillow blocks of both chrome and stainless steel.

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Ball Screws: Ball Screws Select from the dropdown menus below (in any order) to determine the appropriate Ball Screw model. SPEC 1 DIAMETER: Select .375 .500

Mill coolant system design Lubrication is more than meets the eye. May 15, 2001 By: James Dyla. What kind of coolant system you construct for your tube mill or roll ...

End Mill, Drill, and Cutting Tools Manufacturer Melin Tool Company Premium Cobalt HSS and Carbide Endmills, Drills, and Cutting Tools

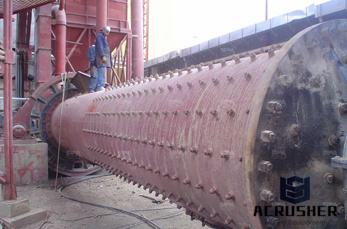

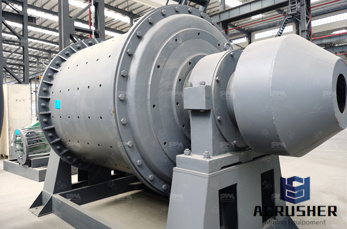

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

From one simple but inspired solution to a misalignment problem in a textile mill in Sweden, and fifteen employees in 1907, SKF has grown to become a

End Mill, Drill, and Cutting Tools Manufacturer Melin Tool Company Premium Cobalt HSS and Carbide Endmills, Drills, and Cutting Tools

Sep 17, 2013· This video provides an overview of how to perform Critical Path Method (CPM) to find the Critical Path and Float using a ...

End milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified ...

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert "Bob" Schilling Presented at the .

Control valve sizing calculator with calculation of control valve flow coefficient Cv, pressure drop and flow rate of control valve

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

Design and build details of my custom CNC Router including CAD files, drawings, and build details. This is a steel fixed gantry style router built specifically to ...

WhatsApp)

WhatsApp)