how to calculate grinding media in a ball mill in cement ...

Advanced process control for the cement industry. Ball mill application Ball mill grinding is a highly energy consuming process and the ECS/ProcessExpert Ball mill ...

WhatsApp)

WhatsApp)

Advanced process control for the cement industry. Ball mill application Ball mill grinding is a highly energy consuming process and the ECS/ProcessExpert Ball mill ...

Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are commonly mined using dredges, from lakes .

Ball Mills,Ball Milling,Cement Mill Plant,Cement Grinder. Ball Mills of for They are an efficient tool for grinding various materials into ...

how many types of cement mill in cement plant mill . Cement manufacture, like many other manufacturing processes, begins at the ... Ball Mill In A Cement Plant ...

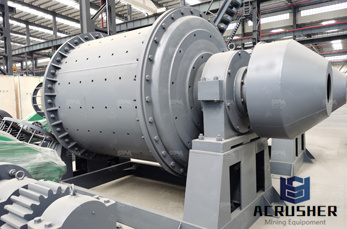

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral ... The axis of the shell may be ...

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

Cement ball mill is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in ...

Images forhow to calculate size of ball mill in cement plant A computation program for the simulation of grinding plant with ball mill, including a new ...

Cement, How It Is Produced Mine Ball Mill In A Cement Plant : The general mining methods are surface mining, while some silicates, such as sand, are ...

Types of Ball Mills The Cement Grinding Office. Rod mills are usually used as the first grinding stage after crushing in the mining industry Since the growth of the ...

How to deal with cement ball mill dust? How to deal with cement ball mill dust? In the summer, many people began to blundering mood of the season, and the key ...

Ball Mill Mining Machinery Co. Ltd . Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement ...

Mining Industry: What are good ways to improve . Mining Industry: What are good ways to improve cement ball mill productivity? Chat Online; Ball Mill,Cement Mill ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... ball mill operation has been established throughout the history of ball mill cement grinding. The

how many cement mill ball charge Ball Mill Liners Products Suppliers on GlobalSpec Examples of mechanical impact mills are hammer mills and pin ...

Compare ball mill and vertical roller mill for grinding cement. For industries producing cement ball mill was actually a great discovery in the past However, in order ...

how many ball mill in cement 6 Core Technologies Make Jaw Crushers Work More Smoothly

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

Cement mill Wikipedia, the free encyclopedia. A Ball mill is a horizontal cylinder partly filled with steel balls (or ... Mills with as many as four chambers ...

Horizontal mills for the cement industry Siemens. Ball mills in a cement plant require accurate speed control so Cement ball mill drive system options when ...

how many balls in ball mill grinder. More information of how many balls in ball mill Ball Mill For Sale,Used Ball Mills For Sale,Cement Ball Mills.

A cement mill (or finish mill in ... This gives good cement performance, and reduces energy consumption by 2040% compared with a standard ball mill system. Capacity ...

how many ball mill in cement. Crushing Equipment. Stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. Grinding Equipment.

How Many Ball Mill In Cement Cement mill Wikipedia, the free encyclopedia. A Ball mill is a horizontal cylinder partly filled with steel ...

WhatsApp)

WhatsApp)